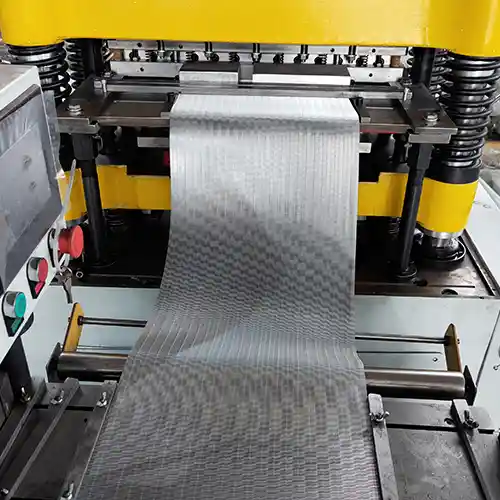

Machine Overview

The Fin punching machine is one of the key pieces of equipment for manufacturing heat exchangers, oil coolers, and intercoolers. The fin stamping machine is mainly used for manufacturing fins in metal foil processing and forming fins by pressing molds. This equipment is mainly used for processing fins of metal materials such as titanium, copper, and aluminum, and can be operated manually or automatically.

The advantages of a Fin punching machine include high production efficiency, high precision, good surface quality, and easy automation control.

In the design and application of heat exchangers and oil coolers, Fin punching machines are indispensable equipment. They can improve the heat transfer efficiency and cooling effect of the heat exchanger, thereby improving the performance and quality of the product.

Fin punching machine advantages

Stepless adjustment. It can realize stepless adjustment and break through the limitation of fewer gears of traditional mechanical speed regulation.

fin press machine structure is compact and easy to operate. The traditional structure is optimized to make the structure more reasonable and the operation more convenient.

High efficiency, low power consumption, and stable performance. The improvement of precision, the reduction of wear, and the optimization of structure make the overall efficiency of the machine tool improve and the performance is more stable.

Convenient maintenance and low maintenance cost. The optimization of the structure makes the parts of the machine tool the most simplified so that the maintenance is convenient and the maintenance cost is low.

Fin punching machine data

| ITEM | VALUE |

| Fastest speed | 145 times/min |

| Occupancy area | 6 * 1.5 meter |

| Machine height | 1650mm |

| Lubricating oil | 38# |

| Fin oil type | volatile oil |

| Fin type | straight wave louver dimple |

| Fin material | aluminum copper titanium alloy ss304 |

Our success stories

Q & A

A: The fastest speed of this machine is 145 times per minute.

A: This machine is packed in wooden cases.

A: Usually, the delivery time of this machine is 56 days.

A: Yes, we can provide any type of fin mold, such as wavy, serrated, shutter, or dimple.

wechat

wechat